About Us

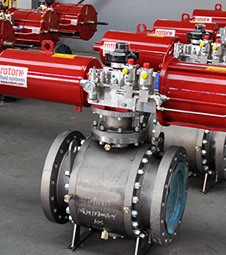

Fully welded ball valves

Welcome to Ranger Valve America Ltd.!

Ranger Valve America Ltd. (Ranger™) provides a wide range of products that are engineered to meet or exceed performance standards and have been configured based on time-tested field experience to serve an array of industries and applications.

Consistent quality -process & design

The foundation for Ranger’s valve capability lies in its process consistency to meet statutory and regulatory requirements, as well as its drive to ensure complete customer satisfaction, improve project economics, extend valve service life, eliminate fugitive emissions, and ensure safe operation. Key processes include:

- Ensuring qualified personnel through training and certification

- Rigorous selection process and on-going testing and auditing of sub-suppliers and vendors

- Detailed quality process framework, including ISO 9001:2015 and API Q1 certification

- Advanced traceability through online documentation support and encompassing MTRs.

- ISO 14001-2015 Environmental Management System

Certified & Registered

Ranger™ believes that the adherence to industry standards and the registration, certification, and scrutiny applied by governing bodies provides a foundation for continual improvement and growth. As such, many products supplied by Ranger™ will carry the API Monogram highlighting that the products conform to API specifications and that the manufacturer has a quality management system in place that is compliant with API Q1 – “an industry-leading quality management standard”*.

- Product certification with relevant recognized bodies including:

- API Q1 – Quality management system

- API 6D – Pipeline valves

- API 600 – Cast steel gate valves

- API 594 – Check valves

- API 602 – Small forged steel

- API 609 – Butterfly valves (incl. TOVs)

- API 6A – Wellhead and tree equipment

Audited & Approved

In addition to the process of certification, the API registration also implies an annual audit and a substantive renewal application every three years. In addition to the industry association’s acceptance and certification, Ranger™ also provides products that have end-user, the engineering community, and major distributor audit approvals.

Field & time tested

Ranger™ represents products that are both field and time tested, and with ongoing input from the large installed base of global (and North American) end-users, engineering teams, and distribution agents, Ranger’s process continues to drive improvements in service life and product performance.

With several decades of focused industry and application experience to draw on, the Ranger™ team has garnered a reputation for providing products that work in even the toughest applications.

Safe, reliable operations

The health, safety and environmental impact of the manufacturing process is also top of mind for Ranger™. As such, the production facility is ISO 14001:2015 certified and follows a strict process to ensure environmental sustainability, including API 624 emission standard for gate and globe valves. Ranger’s investment in process consistency and accuracy has a direct impact on the safe and reliable operation of the products.

Service, Reliability and Support

From engineering to procurement, major project or field support, Ranger™ aims to deliver a valve ownership value second to none in the industry. Underpinned by its systems and a culture of exemplary service, Ranger™ is here to serve. 24/48 Warranty Ranger™ offers an industry-leading warranty on all of its valves as it believes its customers deserve the most reliable product on the market. Furthermore, Ranger’s ISO program ensures a non-conformance and corrective action process that provides both a timely and documented resolution.

Ranger takes pride in having a safe workplace for employees, suppliers, and visitors, and has a solid history of providing a safe and injury-free workplace. Ranger believes that using the correct equipment, planning the work appropriately, and taking ample precautions can maintain the conditions of the workplace and the safety of its people. Time spent planning to conduct safe work is considered time well spent. Additionally, all Ranger employees are expected to conduct their work in a professional manner, which includes keeping their work sites clean and complying with health and safety guidelines. Ranger employees must ensure that they follow safe work practices and wear the appropriate personal protective equipment.

Ranger takes pride in having a safe workplace for employees, suppliers, and visitors, and has a solid history of providing a safe and injury-free workplace. Ranger believes that using the correct equipment, planning the work appropriately, and taking ample precautions can maintain the conditions of the workplace and the safety of its people. Time spent planning to conduct safe work is considered time well spent. Additionally, all Ranger employees are expected to conduct their work in a professional manner, which includes keeping their work sites clean and complying with health and safety guidelines. Ranger employees must ensure that they follow safe work practices and wear the appropriate personal protective equipment.