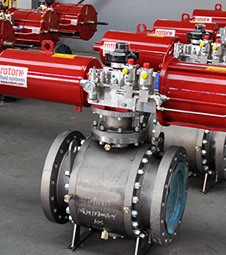

Floating Ball Valves

The RANGER series of two-piece floating ball valves have been engineered to meet both general service and heavy duty applications including petroleum, petrochemical, and industrial. Valves are designed in accordance with API 6D and CSA Z245.15, and they are available in a variety of configurations and materials to meet your specific operational needs.

Design Standards

- Two-piece bolted body design for ease of field service and maintenance

- Cast steel 150, 300 & 600

- Forged steel 600, 900 & 1500

- Firesafe design

- Standard valves meet NACE

- Extreme low torque for actuation savings

- ISO 5211 mounting flanges

- High life cycle

- Independent dual body seals

- Locking device to API 608

- All o-rings are AED (anti-explosive decompression) design

- Gear operators and lifting lugs on 6” bore and larger

- Standard document package BS/EN 10204-3.1

- Low emission capable due to O-ring design

- Exceeds ASME B16.34 minimum wall thickness

- RANGER three-piece forged trunnion ball valves and two-piece cast floating ball valves are certified for use in Safety Integrity Level (SIL 3) applications

Stem Design Features

- Blowout proof stem

- Double anti-static stem

- Adjustable packing

- Triple independent low emission stem seals ensure stem seal integrity

- Two-bolt gland flange

Seat Design Features

- Unique wide flexible seat rings

- Absolute seal in low and high pressure

- RPTFE (15-20% carbon fibre) in 150 & 300 ASME; Devlon V in 600 -1500 ASME

- Self-relieving seats for automatic internal cavity relief

Optional Features

- Body may be coated for corrosion protection

Reference

Design Standard:

- API 608

- API 6D

- CSA Z245.15

- CSA B51-09

- ISO 17292

Face to Face:

- ASME B16.10

Flange:

- ASME B16.5

Marking:

- MSS SP-25

Inspection:

- API 598

Pressure & Temp.:

- ASME B16.34

Quality:

- MSS SP-55

Fire Safe Design:

- ISO 10497, API 607

Sour:

- NACE MR 0175

- ISO 15156-2009

Pressure Testing:

- API 6D and low pressure air seat test

Safety Integrity Level:

- SIL 3

- Self-relieving seats for automatic internal cavity relief