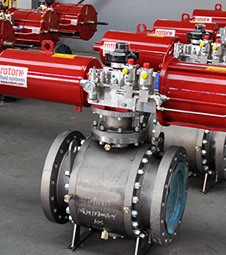

Fully Welded Body Ball Valves

The RANGER series of fully welded ball valves have been engineered to meet both the general service and heavy-duty applications with a focus on buried service.

Key Application(s)

- Oil and natural gas pipelines, as well as urban gas pipeline

Design Features

- Sizes from 2” to 48” (50mm to 1200mm)

- CLASS 150 to 2500

- Operating temperature -196℃ to 593℃ (the range of service temperature may vary for different materials)

- The valve seat is embedded with flexible seal ring for zero leakage of the seal; the valve seat is provided with a preloaded spring that is adaptive to the variation of pressure and temperature, so leakage is not liable to happen

- Integral valve with a welded valve body, free of external leakage, etc.

- Fire resistant construction of all-welded ball valve. Each leakage position is designed with flexible graphite packing or stainless steel mixing graphite to satisfy the fire resisting requirements in case of a fire

- The most advanced support plate structure both at home and abroad is adopted for large diameters to increase the service life and reduce the operating torque of the valve. Thus, the service life of valves is greatly extended

- The directly-buried all-welded ball valve can be buried directly, in which case, no high and large valve pit is required, only a small shallow pit needs to be built on the ground, so the construction cost and the engineering time can be significantly saved

- The full bore of valve convenient for pigging, of small flow resistance and high flow capacity and good flow characteristics

- The valve ball can completely enclose the valve seat when the all-welded ball valve is opened, so the impurities in the medium will not be flushed to the valve seat or the packing surface of the valve body. Hence, the valve body has the same service life as the pipeline due to his special construction.

Reference

Design Standards

- API 6D

- ASME B16.34

Face-to-Face

- ASME B16.10

End Connection

- ASME B16.5

- ASME B16.25

Test Standards

- API 598

- ISO 5208